Contáctenos ahora para una solicitudinfo@ckic.net

- Productos

- Calorímetro

- Analizador Elementales

- 5E-XRF2500 Espectrómetro EDXRFNuevo!

- 5E Series C/H/N Analizador Elementales

- 5E-TCN2200 Analizador de Nitrógeno / Proteína

- 5E Series Analizador Flúor /Cloro

- 5E-HGT2321 Analizador Directo de Mercurio

- 5E-IRS3600 Analizador Automático infrarrojo de Azufre

- 5E-IRSII Analizador infrarrojo de Azufre

- 5E-AS3200B Analilador automático de Azufre de Culombio

- 5E-S3200 Analizador de Azufre de Culombio

- Analizador Termogravimétrico - Analizador Próximo

- 5E-MAG6700 Analizador Termogravimétrico - Analizador Próximo

- 5E-MAC6710 Analizador Termogravimétrico - Analizador Próximo

- 5E-MACIV Analizador Termogravimétrico - Analizador Próximo

- 5E-MVC6700 Analizador Automático de Material Volátil

- 5E-MW Analizador Automático del Humedad

- 5E Series Horno Mufla

- 5E-MIN6150 Mini Horno de Humedad

- 5E Series Horno de Secado

- Determinador de Fusión de Ceniza

- Coquizable carbón Indices Determinador

- Probador de indice de molienda HGI

- Equipos de preparación de Muestras

- 5E-APS Sistema automátizado de. Preparación de Muestras

- 5E-HCB Series Trituradora de Martillo

- 5E-HCA400×260 Trituradora de Martilol para Carbón Húmedo

- 5E-JCA Series Trituradora de Mandibula

- 5E-DCA250×150 Trituradora de Doble Rodillo

- 5E Series Puivearizador

- 5E Series Drvisor de Muestras

- 5E-SSB200 Tamizadora Analítica

- 5E Series Hemamientasl

- Sistema Muestreador

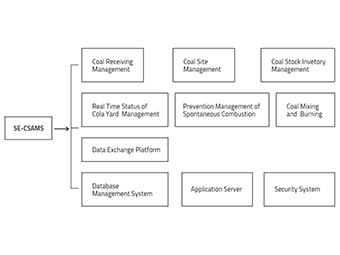

- Sistema de Gestión

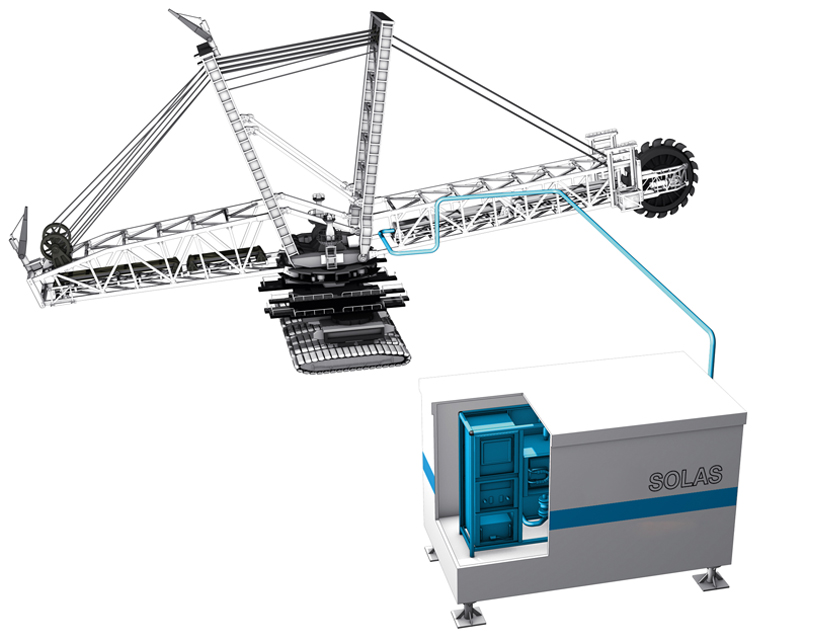

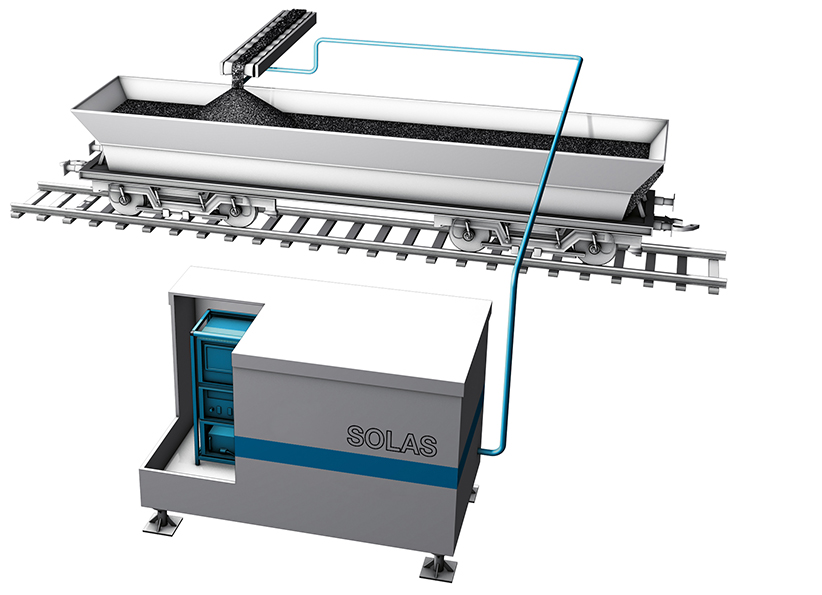

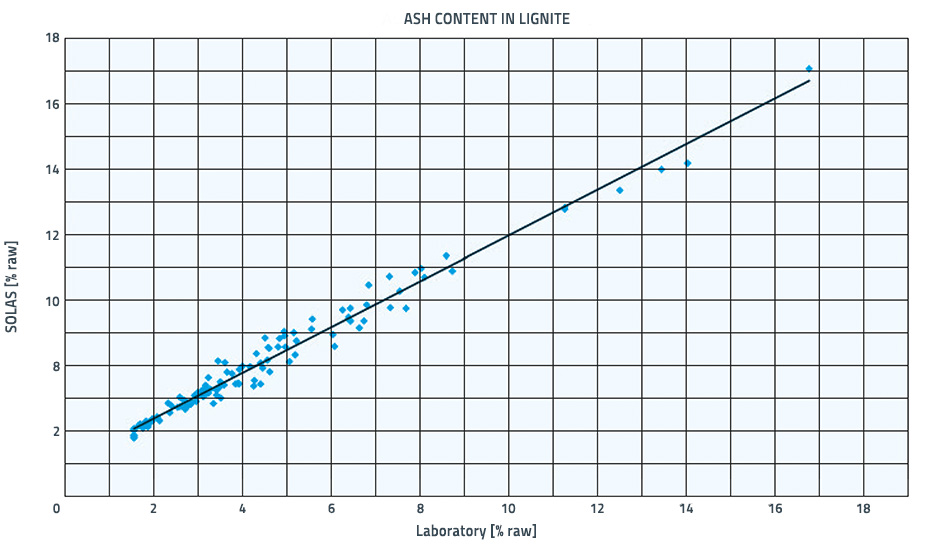

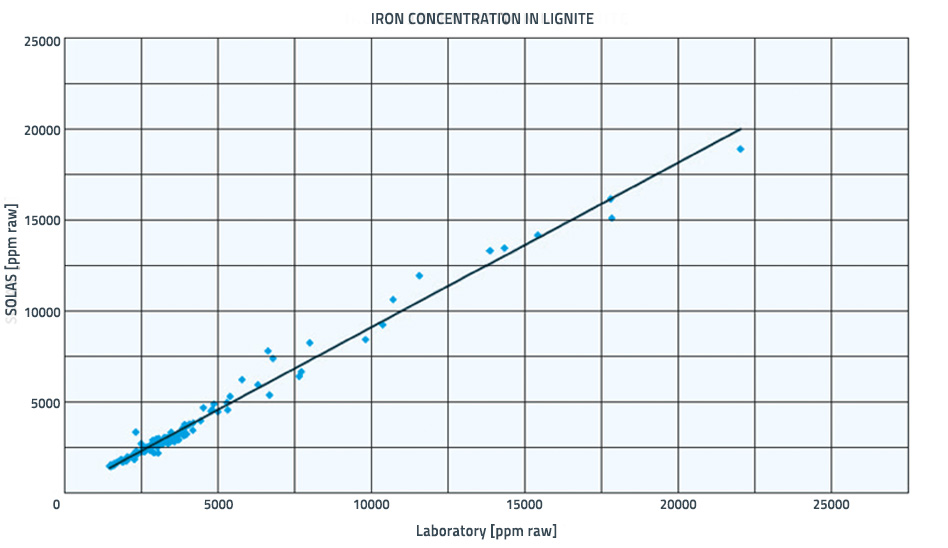

- Analizador Online

- Sistema de Laboratorio Inteligente Robotico

- Piezas de repuesto

- Aplicación

- Novedades

- Soporte

- Compañía

- contacto